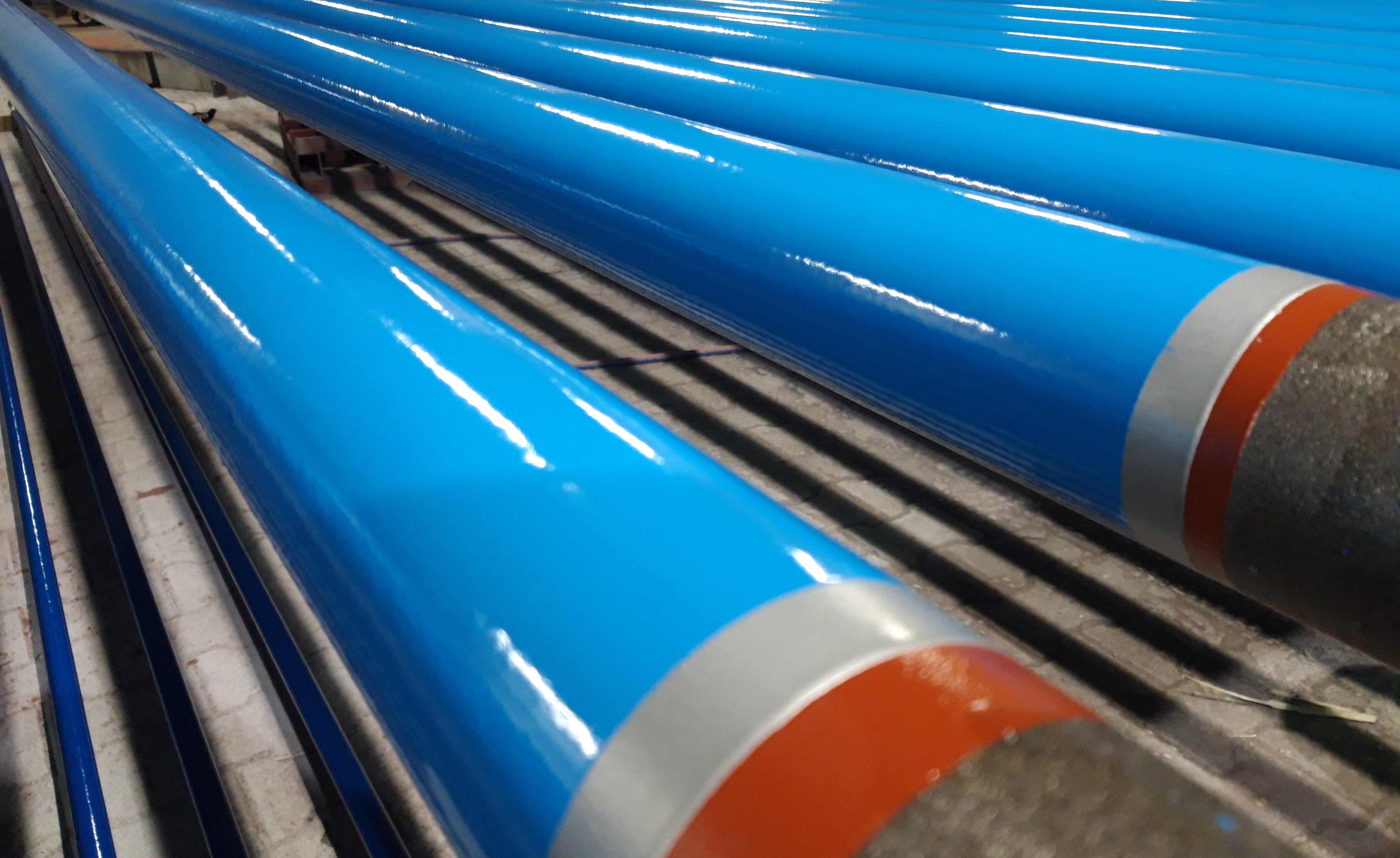

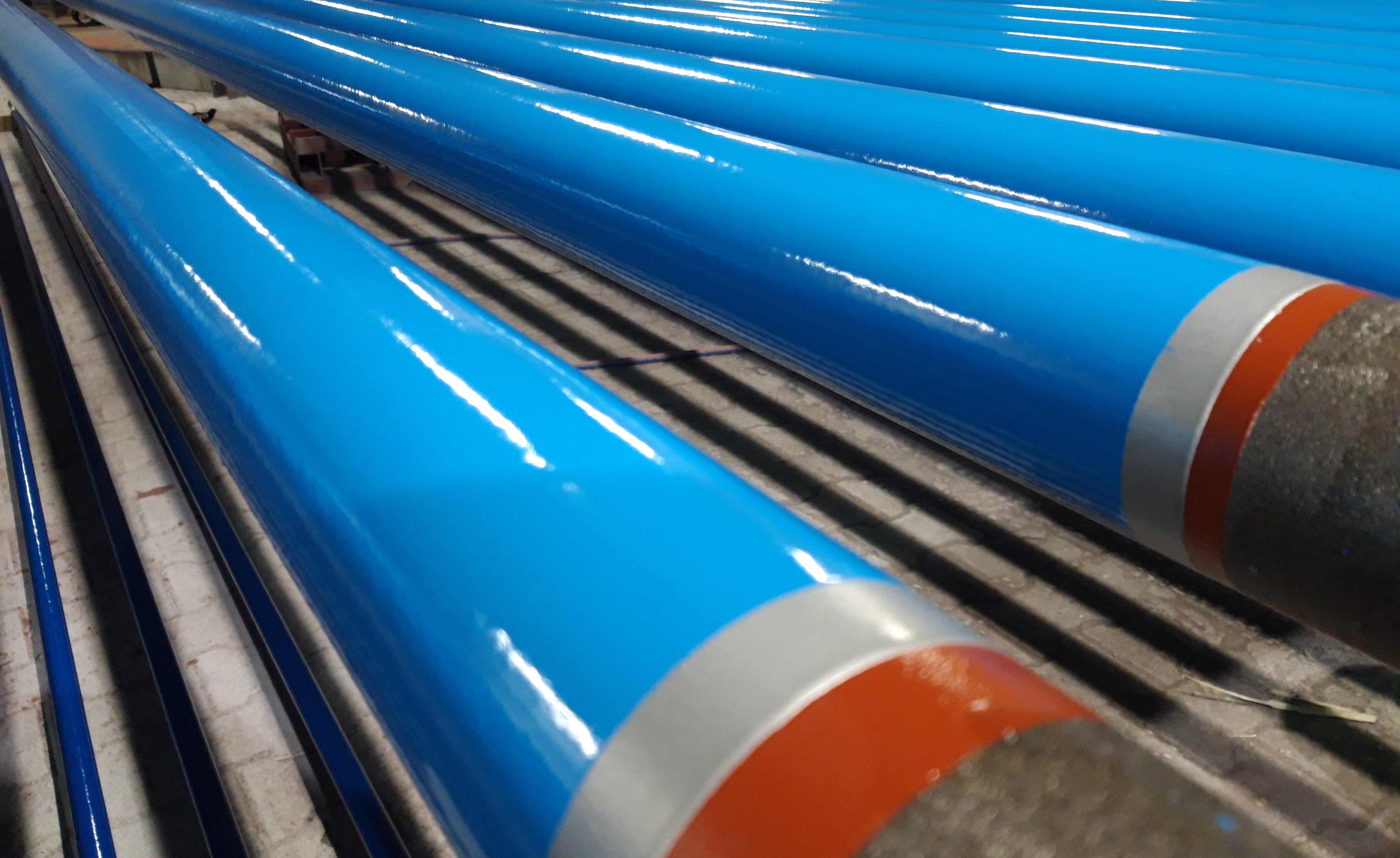

We are a supplier of specialised paint coatings for industrial painting of pipes. We supply factory paint insulation.

We offer painting service of internal surfaces of black and insulated pipes and the application of external coatings to protect above-ground pipelines against corrosion. We have many years of experience, confirmed by references, in painting pipelines operating in various environments, including those with very high humidity and aggressive atmospheres. We paint with epoxies, zinc paints, ethyl silicates and topcoats in the full RAL colour range.

We also offer internal and external paint insulation of steel fittings and welded joints on construction sites. Provides external and internal corrosion protection of above-ground pipeline components.

FEATURES & ADVANTAGES:

- Reliable protection against corrosion

- Ideal adaptation to the operating conditions

- Prefabricated insulation – outstanding strength and durability

- Possibility to cover the joints, on the job-site, after welding

- High aesthetic value

| Standard/Norm |

PN-EN ISO 12944, PN-EN 10301, API RP 5L2 |

| Pipe diameters for external painting |

33.7 mm – 1 420.0 mm |

| Pipe diameters for internal painting |

60.3 mm – 1 420.0 mm |

| Pipe length |

6.0 m – 14.0 m |

| Insulation thickness, other parameters |

According to standards, project data and detailed arrangements |

| Type of paint insulation |

In accordance with the project or order |

| Range of diameters of fittings |

Unlimited |

APPLICATION:

Internal paint coatings are used to paint the internal surfaces of black and insulated pipes. They are used for:

- Gas pipelines

- Drinking water pipelines

- Industrial water and waste water pipes

- Fuel and industrial pipelines in refineries and other chemical plants

- Protective casing pipes

External paint coatings are used to paint the external surfaces of pipes. They provide corrosion protection for above-ground installations:

- Water pipes

- Gas pipelines

- Pipelines in power plants

- Fire protection pipelines

- Chimneys

- Fuel pipelines for petrol stations and refineries

- Other industrial pipelines with operating temperatures from -70˚C to +600˚C

- Protective casing pipes

Corrosivity categories according to ISO 12944 for structures in water or soil:

| Im1 |

Freshwater river installations, hydroelectric power plants |

| Im2 |

Salt/sea water (without cathodic protection), harbour areas, structures such as locks and jetties, coastal structures |

| Im3 |

Soil, underground tanks, piles, pipelines |

| Im4 |

Salt/sea water (with cathodic protection), harbour areas, structures such as locks and jetties, coastal structures |

| Atmospheric-corrosivity categories |

Examples of external environments |

Examples of interior environments |

| C1 – very low |

– |

Heated buildings with clean atmosphere, offices, shops, schools, hotels |

| C2 – low |

Atmosphere with low level of pollution, mainly rural areas |

Unheated buildings where condensation can occur, halls, warehouses, sports halls, supermarket halls |

| C3 – medium |

Urban and industrial atmospheres, moderate sulfur dioxide pollution. Coastal areas with low salinity. |

Production rooms with high humidity and some air pollution, e.g. food plants, laundries, breweries, production halls, dairies |

| C4 – high |

Industrial areas and coastal areas with moderate salinity |

Chemical plants, swimming pools, coastal ship- and boatyards |

| C5 – very high industrial |

Industrial areas with high humidity and aggressive atmosphere, coastal areas with high salinity |

Buildings and areas with almost permanent condensation and high pollution |

| CX – extreme |

Industrial areas with extreme air humidity and aggressive atmosphere, as well as subtropical and tropical atmosphere |

Buildings and areas with almost permanent condensation and an aggressive atmosphere |

WOULD YOU LIKE TO HAVE OTHER DIMENSIONS OF PIPES INDUSTRIALLY PAINTED?

DO YOU NEED CUSTOMISED SOLUTIONS FOR INSULATING FITTINGS AND WELDS?

At the customer’s request, it is possible to carry out painting insulation on pipe sections shorter than 6 m and with a diameter greater than 1 420 mm. We will be happy to help you choose the optimum type of pipe insulation, fittings or welded joints and prepare a fully dedicated solution.

Feel free to contact us:

POLYETHYLENE INSULATION to protect pipes below the ground against corrosion.

We offer a wide range of external poliethylene insulation – 3LPE SYNERGY system for steel pipes. Insulation of steel pipes is an excellent method to increase their lifetime by increasing resistances to corrosion, mechanical damage and chemical or thermal factors.

In our offer you will find a wide range of polyethylene insulations for steel pipes with diameters ranging from 33.7 mm to 1220 mm and lengths from 6 m to 14 m.

We have many years of experience in insulating the outer surfaces of pipelines, proven by numerous references. We also supply polyethylene insulation for various steel parts.

We are a manufacturer of high-quality corrosion protection insulation for protecting steel fittings and welded joints on construction sites.

APPLICATION:

- Insulation of water pipes

- Insulation of gas pipes

- Insulation of waste water pipes and pipes in sewage treatment plants

- Insulation of fuel pipes, industrial pipelines in refineries, petrol stations and other chemical plants

- Insulation of other industrial pipelines with operating temperatures from -70˚C to +50˚C

- Protective pipe insulation

FEATURES & ADVANTAGES:

- Reliable corrosion protection for pipelines below the ground

- Increased resistance to mechanical damage

- Excellent adhesion to the pipe surface

- Lifetime of coatings up to 50 years

- Complete protection of the welding zone of insulated pipes

- Bending of insulated steel pipes is possible without risk of damage

Polyethylene insulation for pipes protection:

| Standard/Norm |

PN-EN 12068:2002 |

| Diameter of the pipe |

33.7 mm – 1 220.0 mm |

| Length of the pipe |

6.0 m – 14.0 m |

| Thickness of insulation |

Class A50 – 1.1 mm

Class B50 – 1.7 mm

Class C50 – 2.4-3.0 mm |

| Tightness test of the coating |

High-voltage defectoscope method

5 kV + 5 kV/mm thickness max 20 kV |

DO YOU NEED POLYETHYLENE INSULATION FOR PIPES OF OTHER DIMENSIONS?

At the customer’s request, it is possible to provide insulation on pipe sections shorter than 6 m and with a diameter greater than 1220 mm. We will be happy to help you to choose the optimum type of steel pipe insulation and select the optimum type of insulation for fittings or welded joints. As a manufacturer, we can prepare a fully dedicated solution for you and prepare a fully dedicated solution.

Do you need advice or a quotation? Contact us:

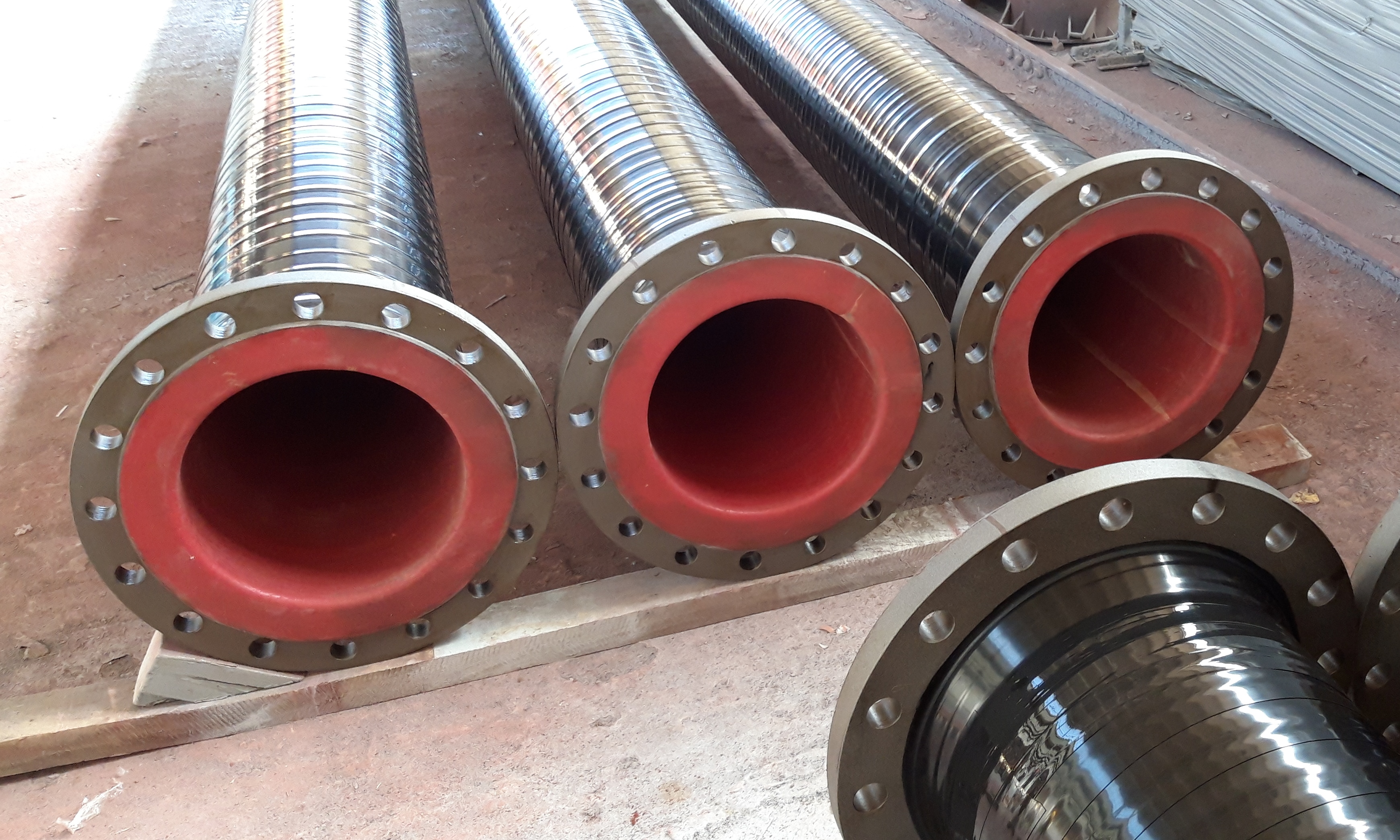

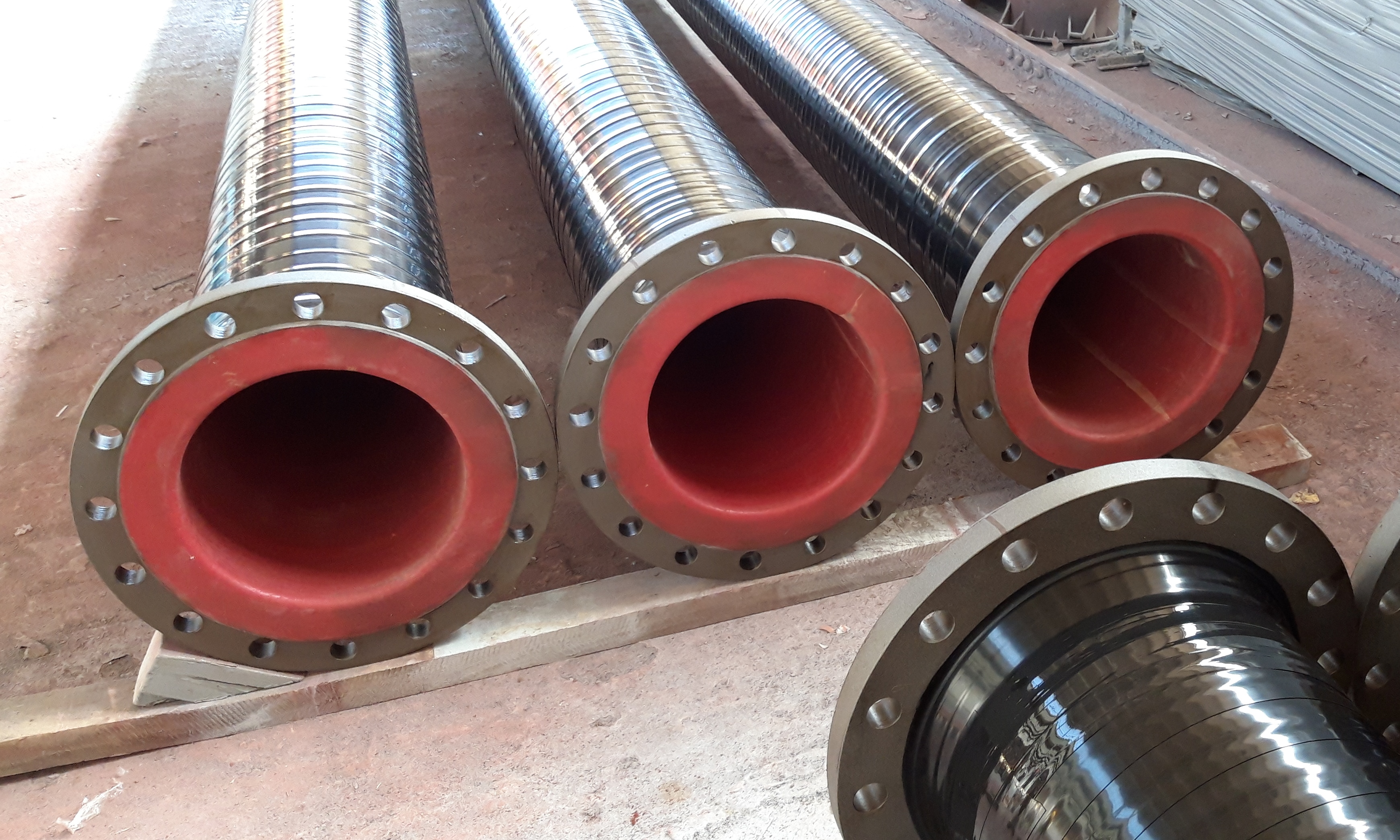

We supply factory-made polyurethane resin insulation on pipes with diameters of 610-1 620 mm (internal pipe insulation) or 273-1 620 mm (external pipe insulation), with lengths of 6-14 m – polyurea insulations. We have many years of experience, confirmed by references, in insulating external and internal pipe surfaces.

ANTICOR also has a highly skilled and specialised team to perform polyurethane coatings on pipes, steel fittings and welded joints on construction sites or at the customer’s premises. The combination of the two offers, both the factory preparation and the availability oft he materials on the construction site, creates a unique offer for the customers, which should further simplify the already complex project handling considerebly.

Advantages of polyurethane insulation

- Longer service life of protected surfaces – longer system life without the need for refurbishment

- Effective protection against corrosion

- Easy transport and assembly of components due to smooth interior coating

- High resistance to contamination

- Insulation layer perfectly adheres to the pipe surface

- Resistant to the damaging effects of chemical agents

Polyurethane internal insulation for pipes

| Standard/Norm |

PN-EN 10290 |

| Range of pipe diameters |

610 mm – 1 620.0 mm |

| Pipe length |

6.0 m – 14.0 m |

| Insulation thickness |

Depending on intended use, manufacturing standard and customer order (min. 400 µm) |

Application

Polyurethane insulations protect the inner surfaces of carrier and protective pipes against corrosion and mechanical damage (abrasion):

- Gas pipelines

- Water pipes (including drinking water pipes)

- Industrial slurry, slag, tailings, aggregates, wastewater and other pipelines

- Drinking water, grain and other reservoirs

Polyurethane external insulation for pipes

| Standard/Norm |

PN-EN ISO 10290 |

| Range of pipe diameters |

273 mm – 1620.0 mm |

| Pipe length |

6.0 m – 14.0 m |

| Insulation thickness |

Klasa A – 1.0 mm

Klasa B – 1.5 mm

According to customer order (min. 400 µm) |

| Testing for tightness of the coating |

High-voltage poroscope method min. 8 kV /mm layer thickness max. 25 kV |

Application

Polyurethane insulation protects both pipes laid in the ground and above ground from corrosion:

- Gas pipelines

- Water pipelines

- Other industrial pipework

- Carrier and protection pipes

At the customer’s request, insulation can be carried out on large pipe sections, fittings and directly on site.

DO YOU NEED POLYURETHANE INSULATION FOR PIPES OF OTHER DIMENSIONS?

DO YOU NEED CUSTOMISED SOLUTIONS FOR INSULATING FITTINGS AND WELDS?

At the customer’s request, it is possible to provide insulation on pipe sections shorter than 6 m and with diameters greater than 1620 mm. We will be happy to help you choose the optimum type of pipe insulation and prepare a fully dedicated solution.

Feel free to contact us:

WE OFFER SHOTBLASTING OF PIPES – ABRASIVE CLEANING OF THE EXTERNAL AND INTERNAL PIPE SURFACES UNTIL THE DESIRED DEGREE OF CLEANLINESS AND ROUGHNESS IS ACHIEVED.

Shotblasting is one of the methods of treating steel components, used to modernise, maintain and protect structures. This process positively influences the aesthetics of the workpieces, strengthens the material structure, refines the surface and prepares it for the application of specialised coatings.

We have our own state-of-the-art shotblasting plant, operated by experienced and trained operators. As a result, we are able to give the workpieces the highest corrosiveness category CX.

As part of our pipe blasting service, we offer the blasting of external and internal pipe surfaces using a suitable blasting machine and the pneumatic blasting of the internal pipe surface using a pneumatic blasting kit.

Blasting of the external surface of pipes

Mechanical treatment by shotblasting of steel pipes external surfaces as a part of technical process.

| Range of pipe diameters |

33.7 mm – 1 220.0 mm |

| Pipe length |

6.0 m – 14.0 m |

Mechanical blasting of the internal surface of pipes

Shotblasting of pipes using an internal shotblasting machine as part of the process line

| Range of pipe diameters |

60.3 mm – 1 220.0 mm |

| Pipe length |

6.0 m – 14.0 m |

Pneumatic blasting of the internal surface of pipes

Shotblasting of pipes with pneumatic blasting kit

| Range of pipe diameters |

108 mm – 355.6 mm |

| Pipe length |

to 16.0 m |

ADVANTAGES OF SHOTBLASTING

- Achieving a surface with the desired degree of cleanliness

- Precise removal of rust, old paint coatings, contaminants, traces of previous treatments, etc.

- Uniformity of the surface and desired roughness

- Preparation of the surface for further treatment (application of paint, insulation, etc.)

DO YOU NEED CUSTOMISED SERVICES FOR SHOTBLASTING PIPES AND FITTINGS?

By prior arrangement, it is possible to carry out shotblasting on fittings and pipe sections shorter than 6 m and with larger diameters than specified above.

Feel free to contact us:

STEEL PIPELINES IN CASINGS – CASING FILLER

We have qualified staff and many years of experience in the anti-corrosion protection industry. We offer products and technologies for protecting service pipes in the Casing Filler casing pipe system. This technology consists in tightly filling the space with ANTICOR Syntetix® Casing Filler material. It is the most effective solution to prevent corrosion of steel pipelines in steel casings. After the ANTICOR Syntetix® Casing Filler material is injected into the inter-pipe space, the access of water and oxygen is completely eliminated, which are the direct cause of corrosion processes on the operated pipeline, and also cause internal corrosion of the casing pipe.

ANTICOR Syntetix® CF – is a material with anticorrosive properties. Protects against chemical and electrochemical corrosion. Contains stress corrosion cracking (SCC) inhibitors and antioxidants. The use of a special formula of synthetic products allowed for high adhesion to steel and plastic surfaces. It does not contain substances harmful to health and the environment.

ANTICOR Syntetix Casing Filler is intended for corrosion protection of gas pipeline crossings through terrain obstacles in underground casing pipes, both in the case of newly built and existing pipes. In the case of existing exceedances, where a galvanic connection of the service pipe with the casing pipe was found, the filling mass introduced into the inter-pipe space is a means of inhibiting the corrosion progress of the service pipe. The filling mass is introduced into the inter-tube space to fill it completely. Thanks to this, soil electrolyte cannot get into the inter-pipe space. The ends of the casing pipe should be secured in a tight and durable manner – in the Casing Closure technology, so that the filling mass during application and use after application does not escape into the environment.

APPLICATION:

- Securing the service pipe in the casing pipe on newly built sections of pipelines

- Repairing of the service pipe insulation in the casing pipe on used pipelines

FEATURES AND ADVANTAGES:

- The most effective and cheapest method of repairing an electrolytic short in a protective tube

- Tightly fills the space between the pipes, eliminating residual water, oxygen and moisture

- Perfectly protects against stray currents

- Contains additives that improve functional properties, eg corrosion inhibitors, antioxidants, etc.

- Does not contain ingredients harmful to health and the environment

- Protects against corrosion inside the protective tube

- Insulates against the penetration of corrosive agents

- Reduces costs associated with cathodic protection of pipelines

- Has stable properties during many years of operation

- Does not harden, does not crumble, stays flexible forever and retains optimal sealing properties

ANTICOR Syntetix CF mass has special anti-corrosion and sealing properties. It retains its parameters throughout the entire period of use. It has a Technical Recommendation and a National Technical Assessment issued by the Oil and Gas Institute, classifying the product as safe. ANTICOR Syntetix Casing Filler is not in any state of aggregation: explosive, flammable, toxic, carcinogenic, mutagenic, harmful, corrosive, irritating, allergenic, dangerous for the environment, dangerous for living organisms, a substance with oxidizing properties.

Do you need advice or a quotation? Contact us:

We create ANTICORs’ products specially for you.

Thank you for choosing our solutions.

Welcome to the ANTICOR’s World